Solution for companies which have organic waste, wastewater from industrial production, agricultural by-products, animal waste or their own energy crops.

A solution resulting from the vast experience in the agroindustrial sector, which aims to provide a system adapted to the needs and potential of each project.

CSTR COVERED LAGOON DIGESTER

Aqualimpia (AQL) has developed a topicalized industrial CSTR (continuous-flow stirred tank reactor) covered lagoon digester plant model adapted to the climatic conditions, extensive available areas and construction materials existing in tropical countries. The design of this type of biodigester is based on German technologies and standards. The civil work is carried out with construction materials available in tropical countries, appropriate for the climatic conditions of the tropical climate regions. All the equipment (agitators, blowers, pumps, valves, membrane, flares, etc.) that are installed in our digesters are manufactured in Germany or in other European countries.

BENEFITS OF BIOGAS PLANTS

- Biogas from an anaerobic digester can run a generator to meet on-farm energy and eliminate utility bills.

- Biogas can be used in the own farm or can sold to the local utility at a profit.

- Biogas can be, injected into natural gas pipelines and used as a cleaner burning CNG for transportation fuel.

- Dry solids from a digester can be used as pathogen-free clean cow bedding or as a peat moss replacement

CSTR covered lagoon digester

LAGOON DIGESTER FOR DAIRY WASTE WATER

Excellent ratio between CAPEX/OPEX/biogas production for different types of organic substrates

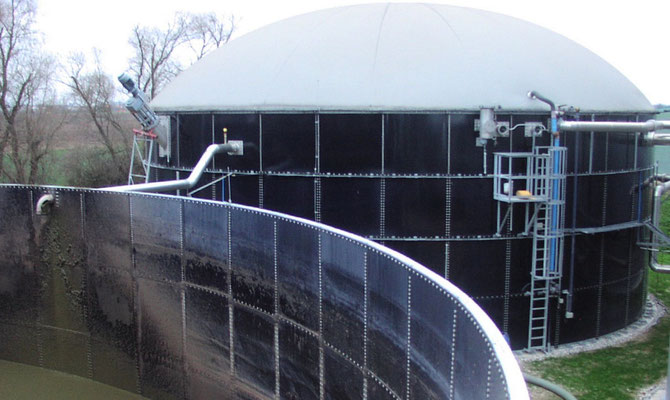

CSTR GLASS LINED STEEL TANK DIGESTER

We do also build our biogas plant on the basis of a glass lined (enameled) steel tank. Steel-enamelling is a thermal process that takes place in the enamelling furnace at above 800°C. A glass layer forms on the outside that will bond strongly to the steel in a chemically-physical fusing process. The outstanding benefits of both materials are:

- Glass protects from corrosion

- Steel gives the strenght and flexibility

- Impact and abrasion resistant

- Hygenic surface

- No bacteria on the surface

- Temperature resistant

- Maintenance free

Characteristics of our AD digestion plants: High performance, less downtime, high durability and low price. Good reasons for a first-class service. Do not save money in the wrong place, but profit by short response times, high availability of spare parts and qualified consultation. We invite you to experience new quality standards for technical service.

No matter what substrates you want to use – farm slurry, food or industrial waste: The right return will convince you of our plant concepts. We do have experience in the design and construction of biogasplants for:

- Slaughterhouse residues and waste water

- Wastewater and agroindustrial processes.

- Dairy residues.

- Household waste

- Waste of livestock farms, poultry, pigs, etc.

- All types of agricultural organic waste: coffee pulp, corn remains, fruit waste, sugarcane bagasse, potato residues, vegetables, banana waste, etc.

- Agroindustrial waste produced in canning factories, fruit packing and juice extractors,

- African palm oil extractors (POME)

- Plasma factories, blood processing industry.

- Waste of chicken and meat processors.

- Seafood waste and waste water.

- Landfills, household waste, sewage .of waste water plants

- Residues from the production of sugar, alcohols and liquors.

- Chicken manure

- Waste from the food industry

- Out-of-date foodstuffs from the retail trade

Our company is experienced in working with clients and performing installations across the world.

New construction

We do design and construct anaerobic digestion plants, according to the highest German standards. We do select a lagoon digester or steel tank digester depending on the topography, soil, substrate and economical conditions.

Our systems are designed based on German technical specifications. The biogas plants can be built using your existing structures and making maximum use of existing construction materials in each country in order to reduce construction costs.

We do design a tank above ground or a lagoon digester according to your requirements.

RePowering

There are a lot of biogas plants, which not operate efficiently and not produce enough biogas or are not in operation. This causes an enormous impact on the economic conditions of the biogas plant.

To achieve the maximum capacity of the biogas plant we offer technical and biological solutions to increase reliability and efficiency of the biogas plants in order to optimize their performance.

Aqualimpia provides an individual, tailor made service which includes:

Planning site visits to your biogas plant, inspect the area conditions, take samples and make an analysis of the substrate and biogas quality provide technical and biological solutions, and analyze the customer’s needs

For this service we do have specialized equipment for doing biological tests and measurements on site.

TEST EQUIPMENT FOR ANALYSIS OF BIOLOGICAL CONDITIONS ON BIOGAS PLANTS