COVERED LAGOON DIGESTER

Aqualimpia Engineering has developed a tropicalized CSTR lagoon digester for the treatment of wastewater with high organic content and organic solids. These systems are designed and constructed with german engineering knowledge and are highly efficient.

The technology we offer has been built from over 30 years of experience in the design and construction of biogas plants. Our expertise has helped us to create a tropicalized covered lagoon system which is very efficient, economical and can be constructed by local companies. Only the technical equipment must be imported from Germany.

cstr covered lagoon digester

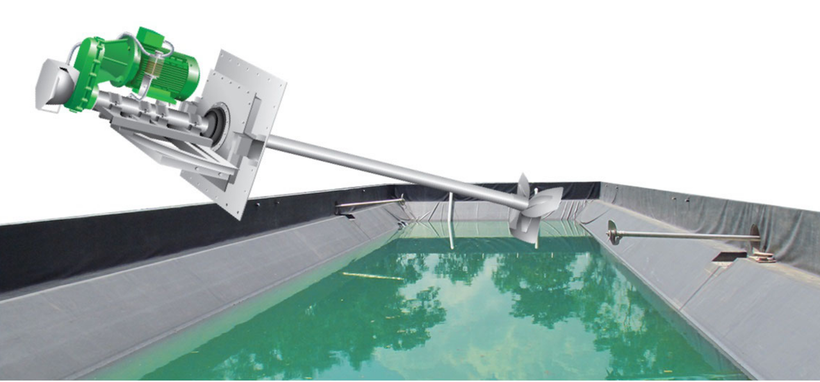

Our digester are CSTR systems with mechanical agitation to improve biogas production and avoid the formation of scum and foam. Through the agitation will be also improved the biogas production and a better degradation of COD.

We install in all our digester a pumping system to extract the sludge which sediment at the bottom of the lagoon.

On this way, we do prevent that after a few years of operation the digester will be filled with sludge.

Blankets of scum may form during a startup or after a few years of operation. During startup a thin zone of high volatile acid content may become localized at the digester surface. Under a mature system a thick, black layer of grease, vegetable matter, and concentrated sludge may cover the entire surface.

Under a mature system the breakdown of scum at the surface of the digester may cause foaming. When scum degrades, a pocket of high volatile acid content develops. The acids produce a condition that is similar to startup. Stratification of non-digested solids near the surface causes foaming.

If foam and scum production in an anaerobic digester is a severe and frequent problem that we have solve in our covered lagoon digester through the instalation of agitators.

AQL CSTR lagoon digester have become the industry leaders in anaerobic digestion because of its proven ability to make systems which work efficiently. Our systems are tailored to the unique site and business of each client.

This maximizes energy production and waste management, while minimizing cost. With more than 50 installations internationally, AQL digesters use proven german technology that completes systems on time and on budget.

Highlights of our covered lagoon digester.

- Engineering made in Germany.

- CSTR digester with german agitators.

- Sludge extraction to prevent lagoon sedimentation.

- One pice EPDM membrane 2 mm thick to cover de lagoon.

- Lined lagoon bottom to prevent filtration in ground water.

- Stainless steel flares made in Germany.

- H2S reduction with biological process.

- With sludge separation for the production of organic fertilizer.

- Tailor made design.

- Reasonably priced.

The CSTR stirred, lined digester is a hybrid system that begins with a covered lagoon, with the addition of a lining, sludge extraction and a mixing system. The system is able to handle all kinds of substrates, and is relatively inexpensive to build and operate.

SLUDGE TREATMENT IN COVERED Cstr DIGESTERS

In the majority of the digesters that Aqualimpia has evaluated, sludge is chemically treated using flocculants and is never extracted based on the degree of mineralization of the sludges or their age. Fresh, undigested sludge is extracted, which still contains a lot of organic load and fats which make it difficult to separate and dry.

Digestate and sludge from biodigesters that treat POME can cause high operating costs if they are not extracted following technical recommendations. If the sludge is extracted without knowing his mineralization grade, it will contain high contents of organic compounds, which are sticky and greasy. Therefore, they cannot be separated from the liquid component and they are not properly dehydrated in sludge drying beds

Aqualimpia has developed a sludge extraction process that takes into account the degree of mineralization of the sludge and the content of dry mass and volatile solids of the sludge. These are removed and conducted through a solids separator. The separated sludge is dried in a cell of the sludge drying beds and the liquid component is recirculated to the biodigester or is also dried in special cells of the sludge drying bed.

SLUDGE DRYING BEDS FOR DIGESTERS

FERTILIZER PRODUCTION IN DIGESTER PLANTS

© Photos all right reserved by Aqualimpia Engineering e.K. / Germany